Computational fluid dynamics (CFD) is a branch of fluid mechanics that uses numerical analysis and data structures to analyze and solve problems that involve fluid flows. Computers are used to perform the calculations required to simulate the free-stream flow of the fluid, and the interaction of the fluid (liquids and gases) with surfaces defined by boundary conditions.

Min-Tec is Using CFD To Develop & to design the Equipment as Below:

Before the engineering Developments have been started, the system concept has been divided into several items but some of them were similar in all under development systems.

The Eng. Department tried to make a logical way to develop this project in a way that make easier the future Heating Systems using modular modules and components trying to select more easy by the clients.

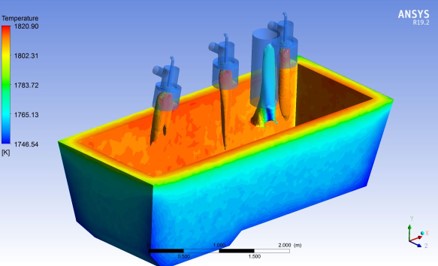

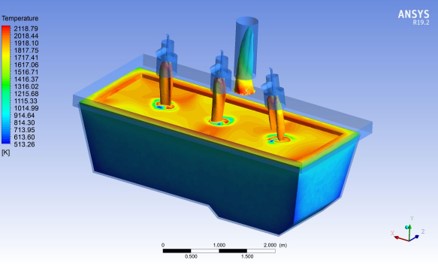

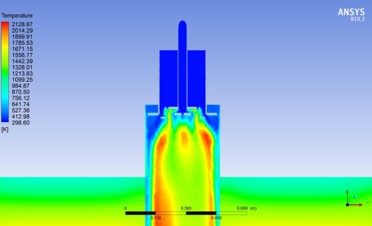

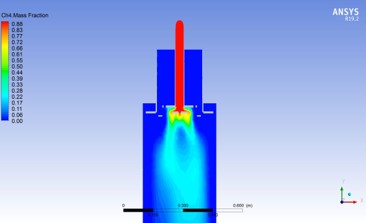

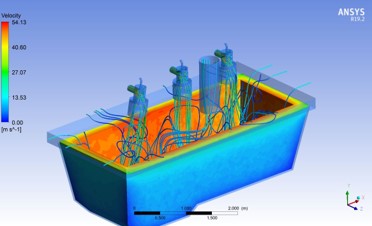

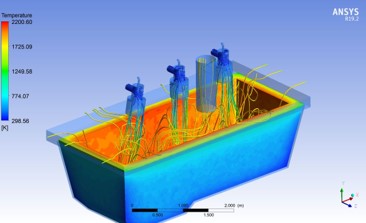

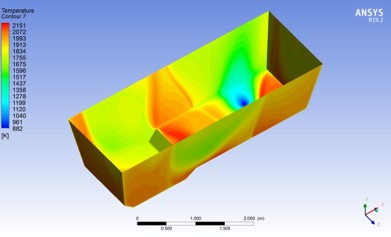

TUNDISH Analytical Model

1. Thermal conductivity calculation (Ladle & Tundish) to determine and Solve essential equation.

2.The Results:

Data Validation has been started when the Burneres manufactured, a pilot tets facilities and the Burners has been tetsed in several operational conditions. The tests have been done under High- Solidity Axial Flow CFD Modeling team supervision and the results used as a feed back for our recalculations. Finally these tests, recalculations and computional analysis made some modifications on the Burners , Tundish and Laddle cover Refractorie’s Enginieering & Design.

High-Solidity Axial Flow Agitators are using for Bio-Leaching Bacteria preparation and Bio-Leaching Copper Extraction, We Use CFD modeling to design and make optimization on agitation Tanks with following targets:

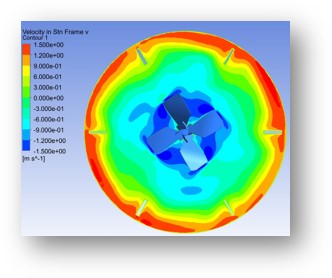

Figure 1. velocity (y-component) at blade plane section

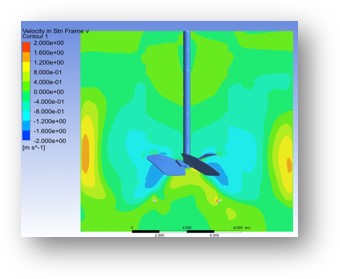

Figure 1. velocity (y-component) at blade plane section  Figure 2. velocity (y-component) at symmetric plane (x=0)

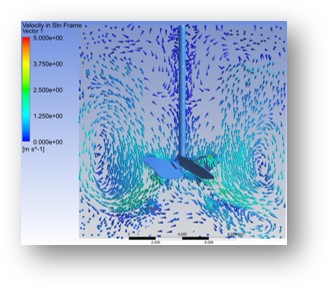

Figure 2. velocity (y-component) at symmetric plane (x=0)  Figure 3. velocity vector at symmetric plane (x=0)

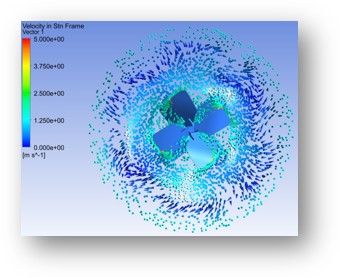

Figure 3. velocity vector at symmetric plane (x=0)  Figure 4. velocity vectors at blade plane section

Figure 4. velocity vectors at blade plane section

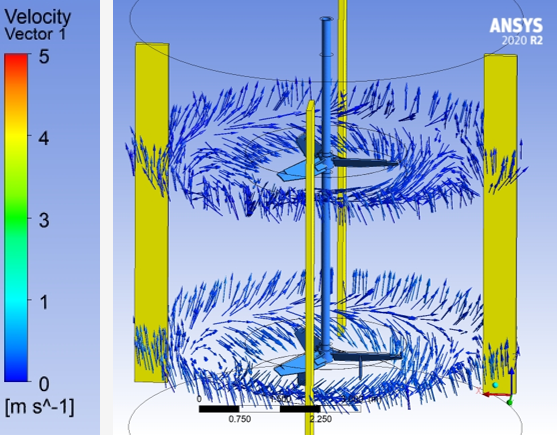

Agitators >CFD Analysis to Velocity Vectors Evaluations:

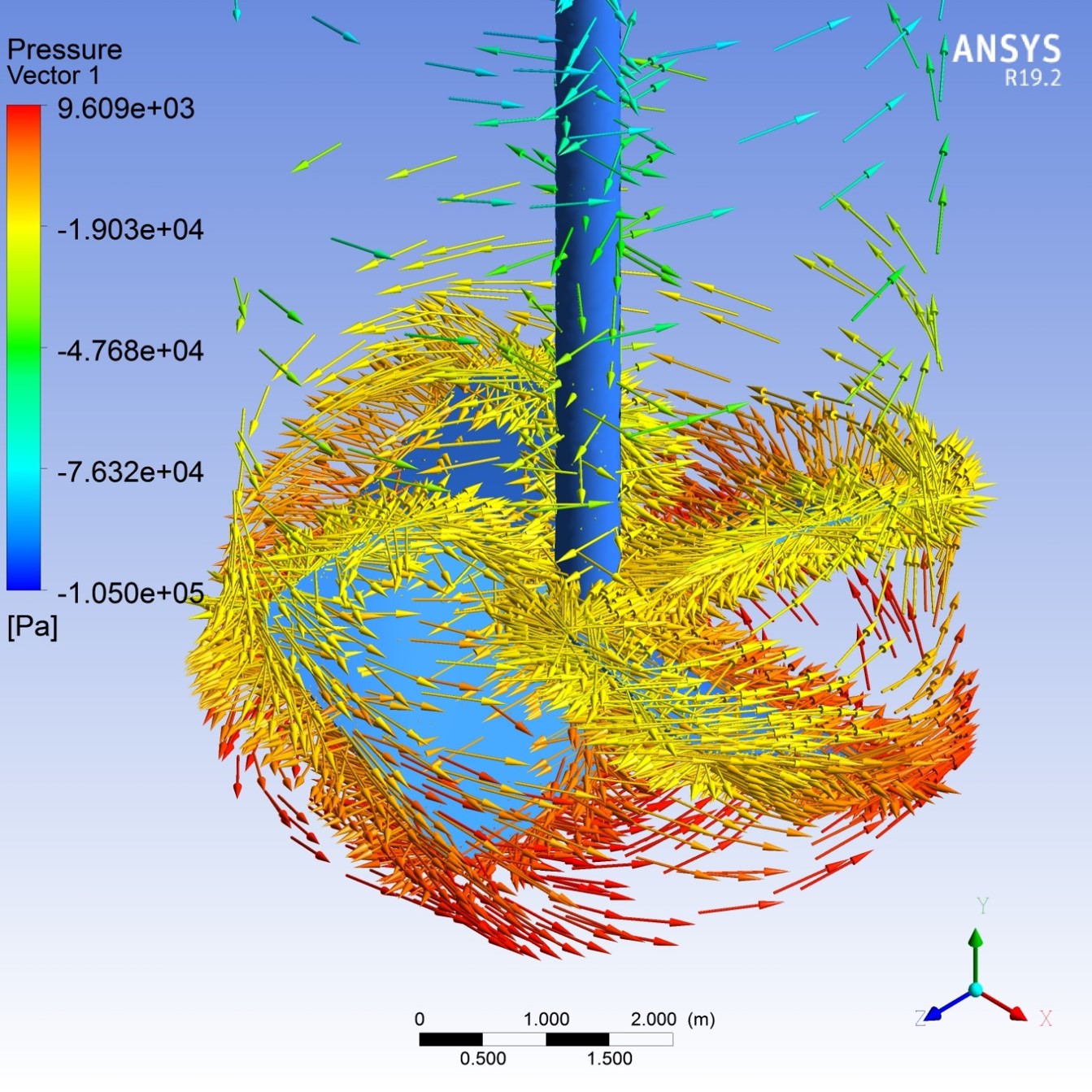

Figure 1. Velocity vectors around the impeller colored by the pressure (isometric view)

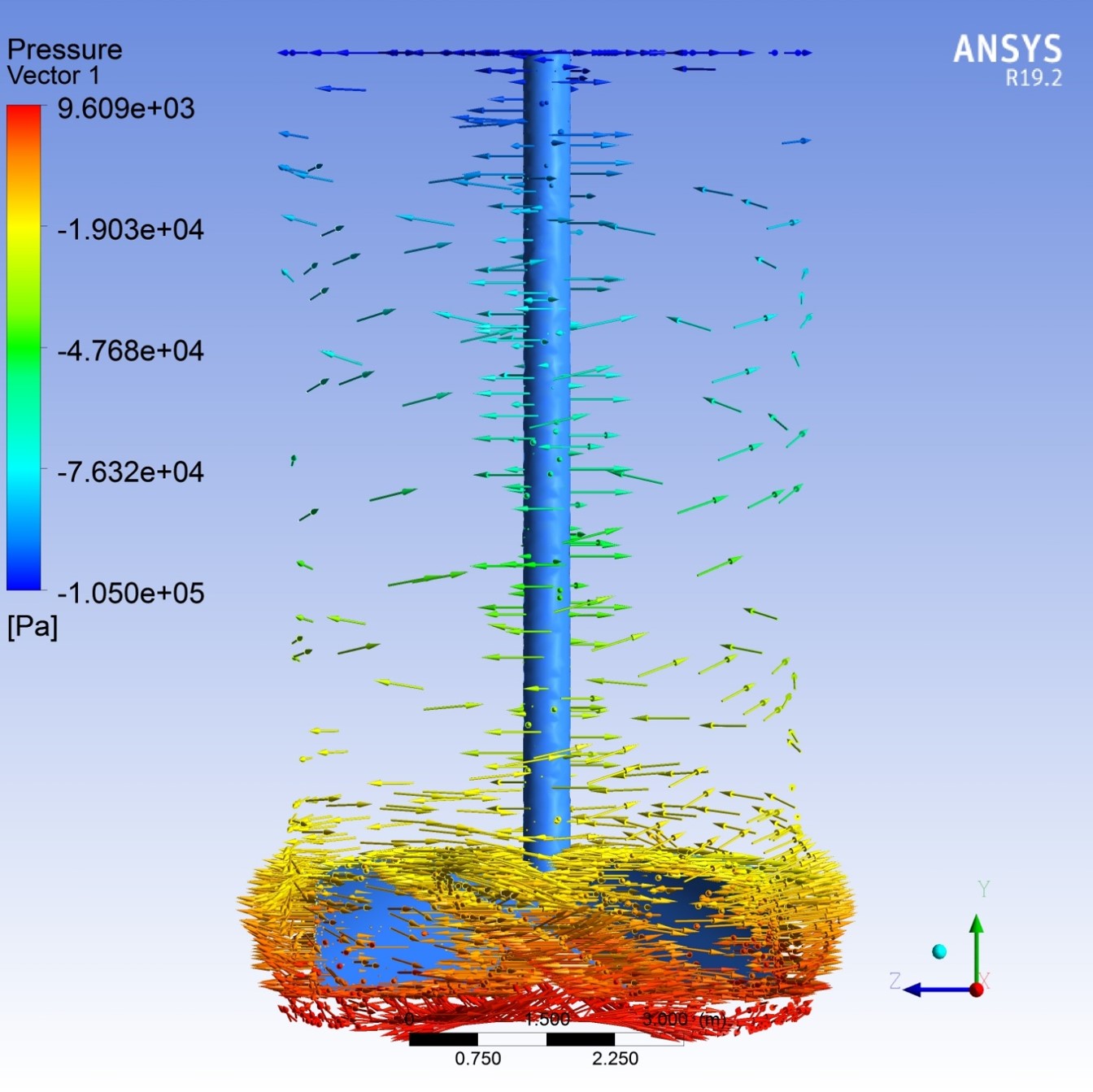

Figure 1. Velocity vectors around the impeller colored by the pressure (isometric view) Figure 2. Velocity vectors around the impeller colored by the pressure (side view)

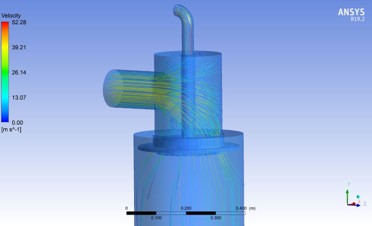

Figure 2. Velocity vectors around the impeller colored by the pressure (side view)Spurger >CFD Analysis to Air Ejection Evaluations:

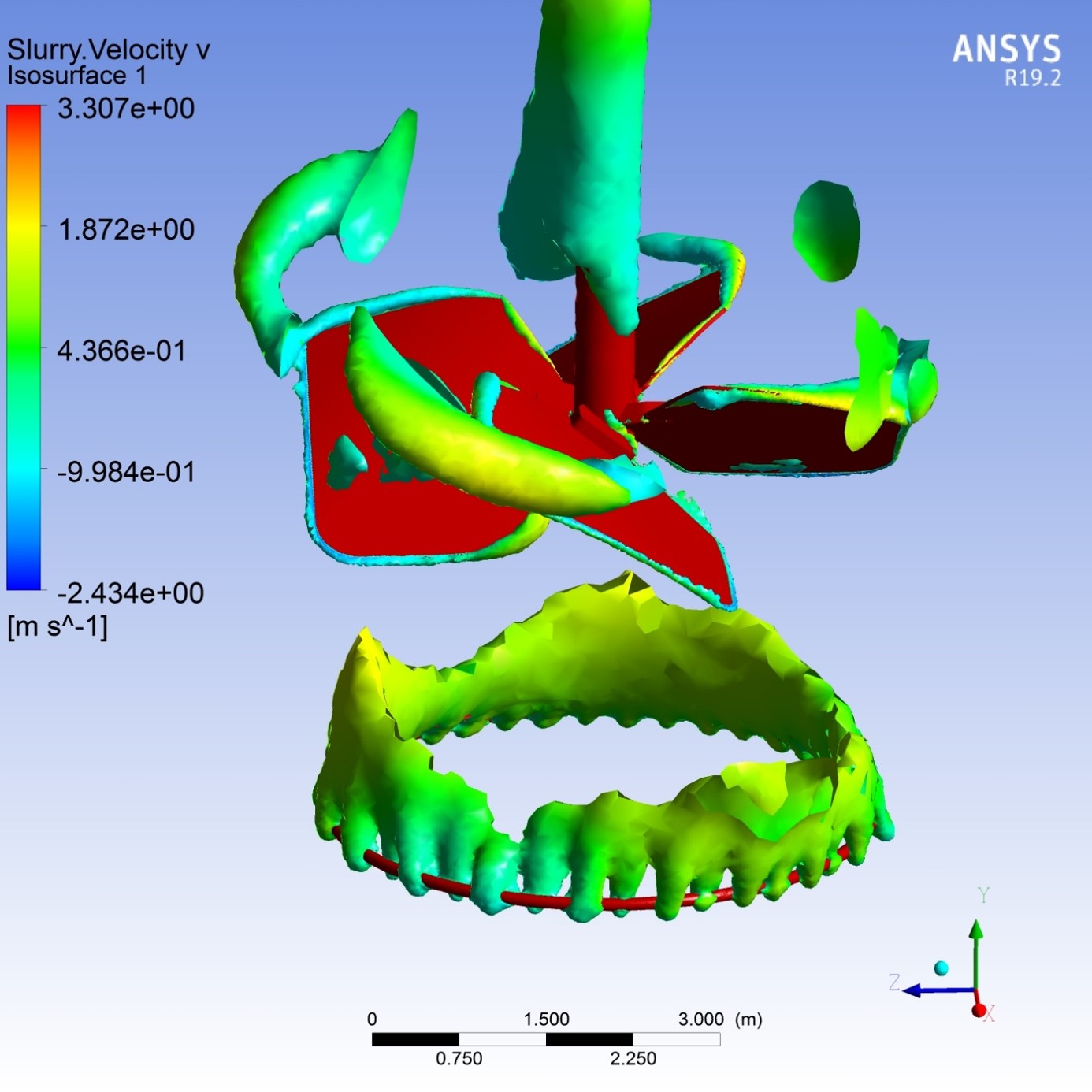

Figure 1. Iso-surface of injected air at volume fraction of 0.1, colored by axial velocity

Figure 1. Iso-surface of injected air at volume fraction of 0.1, colored by axial velocity

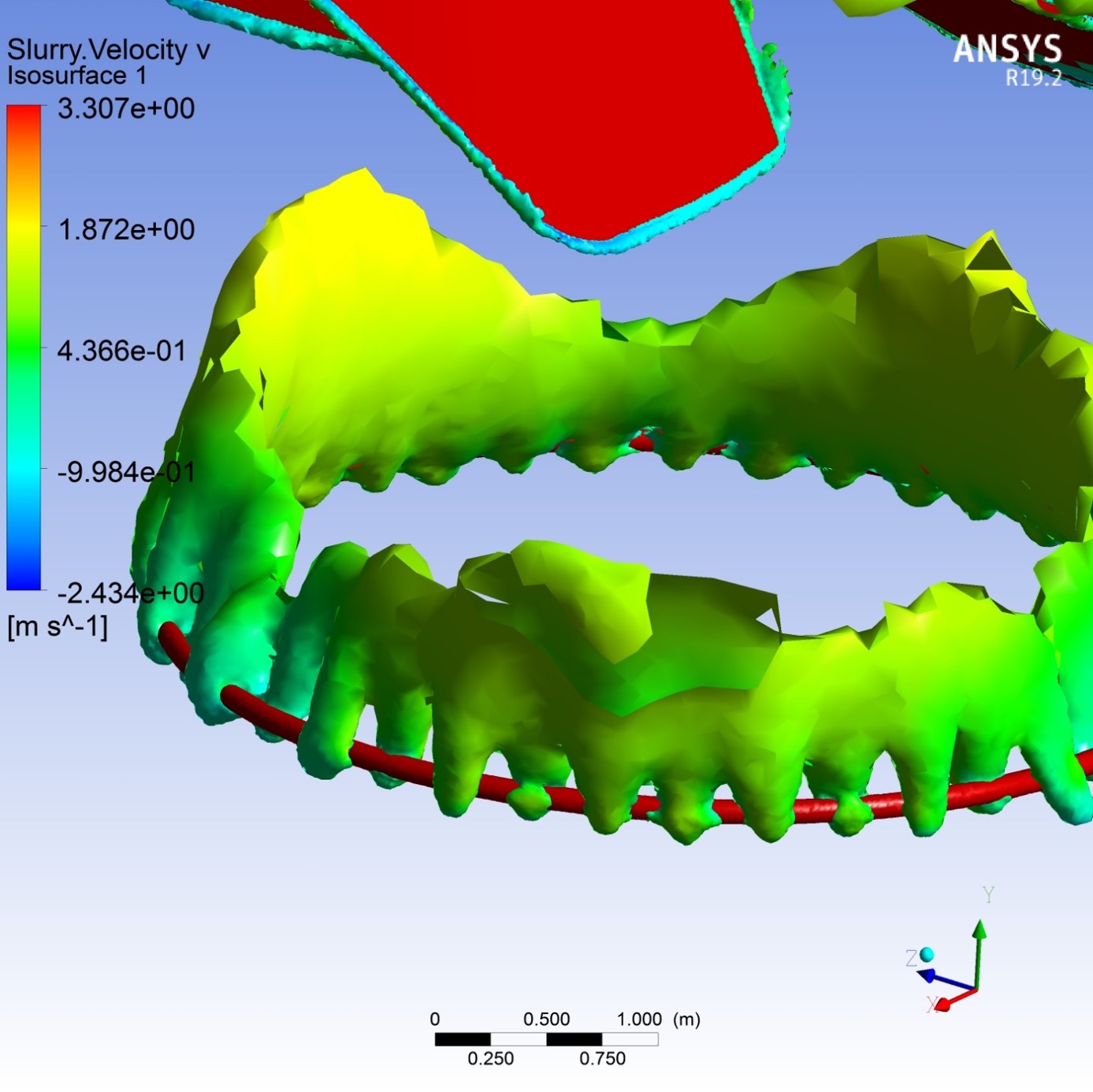

Figure 2. Iso-surface of injected air at volume fraction of 0.1, colored by axial velocity

Figure 2. Iso-surface of injected air at volume fraction of 0.1, colored by axial velocity

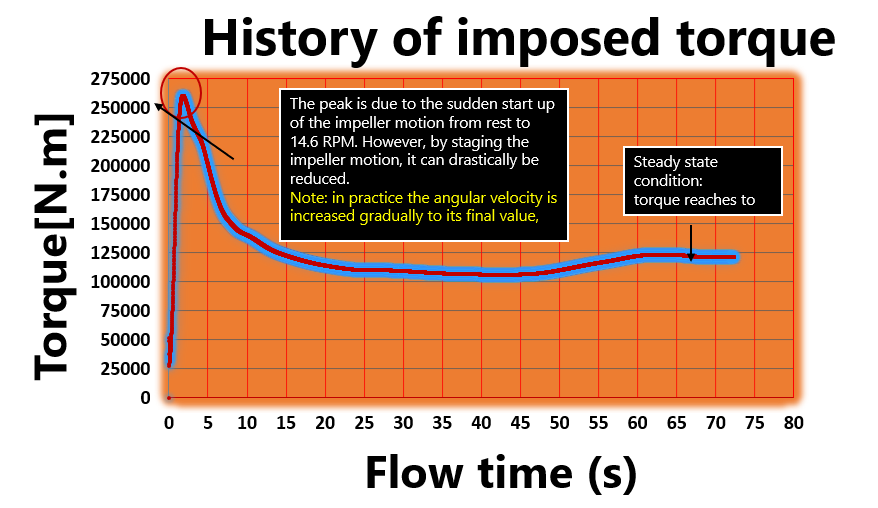

Agitators >CFD Analysis to mechanical evaluations

Hi-Efficiency Impeller CFD Modeling

Figure 1. velocity vector around blades

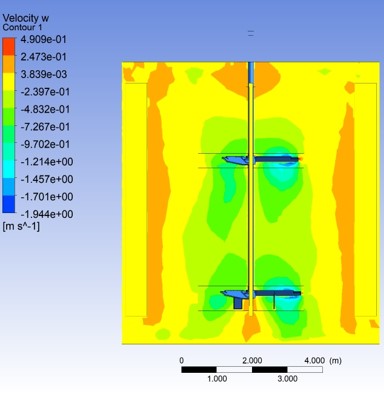

Figure 1. velocity vector around blades  Figure 2. velocity contours of vertical velocity (z-component)

Figure 2. velocity contours of vertical velocity (z-component)

Negative vertical velocity at the center of the tank compared with the positive ones near walls. Upward velocity of 0.247 m/s compared with rule of thumb design calculations value of 0.42 m/s.

Center Shaft >CFD Analysis to Air Ejection Evaluations:

.png)

Blue: Low volume fraction of air

Red: High volume fraction of air

DO distribution may or may not fulfill chemical reaction needs.

Agitators >CFD Analysis to mechanical evaluations :

.png)

It seems that there is an unsymmetric bending on the shaft.

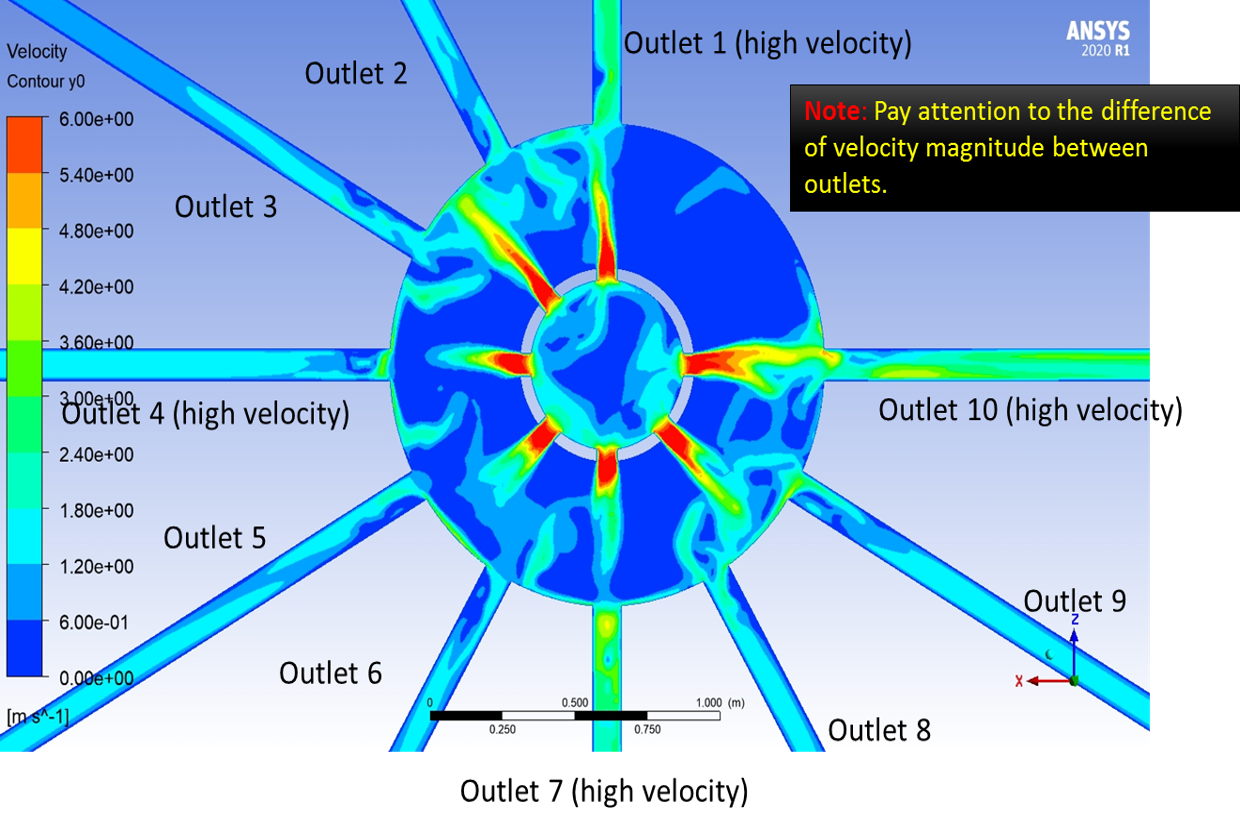

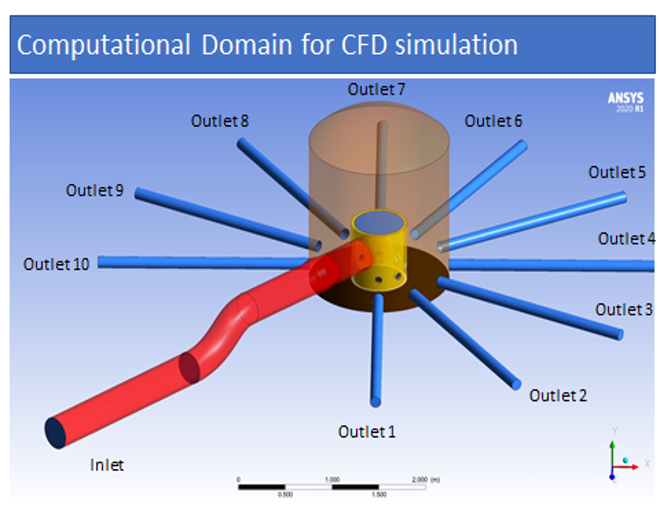

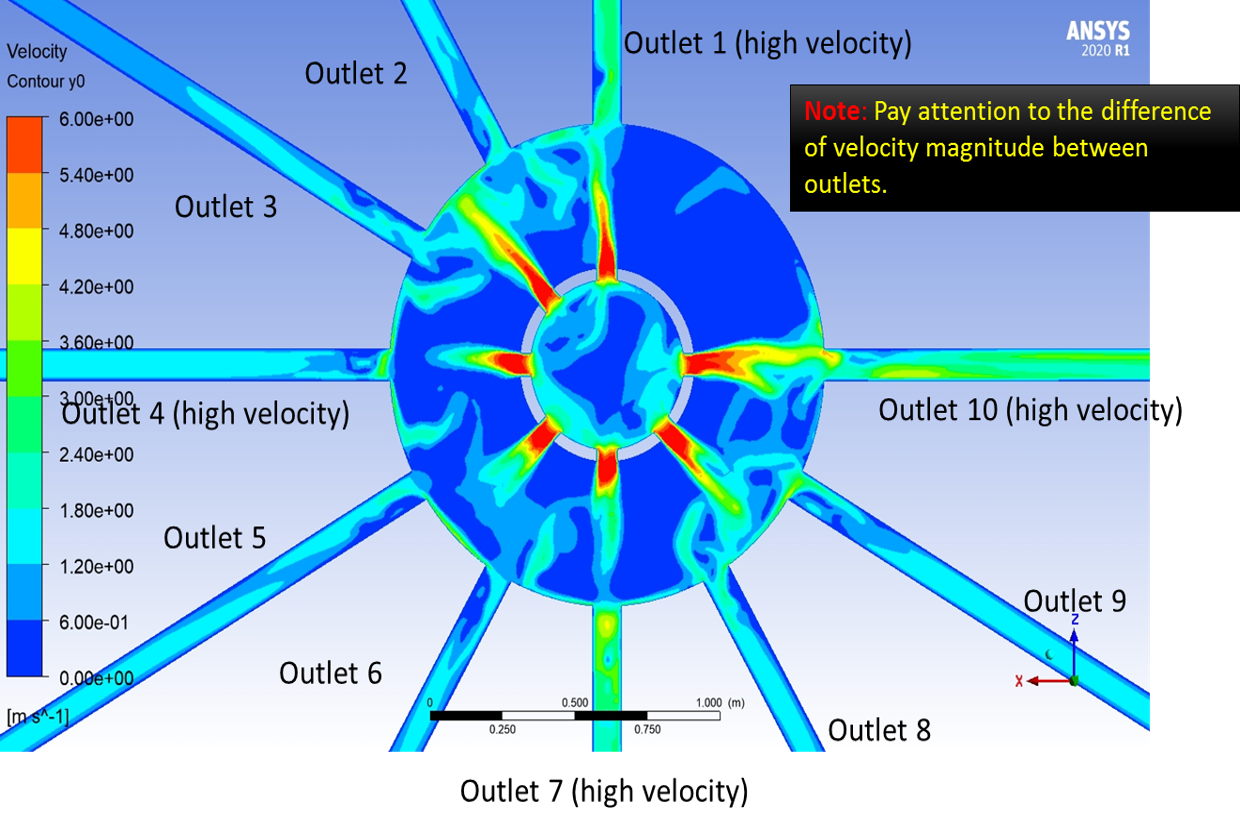

In this project CFD simulations were used to model the behaviour of tailings in distributions tank. Special interest in modelling was to study the Material deposition in the dead zones. Modelling was done in a simplified 3-dimensional geometry. The Front Figure shows the schematic drawing of the modelling domain.

FLUID FLOW of MINE TAILINGS in DISTRIBUTION TANK

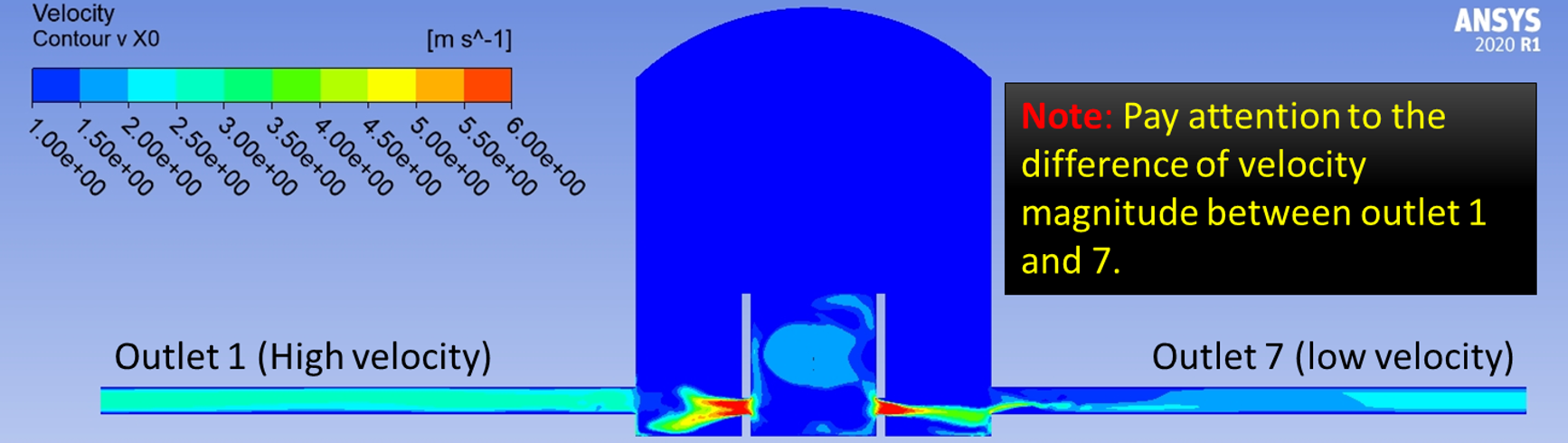

Velocity Distribution on Outlet Orifice

Velocity Distribution on Outlet Orifice

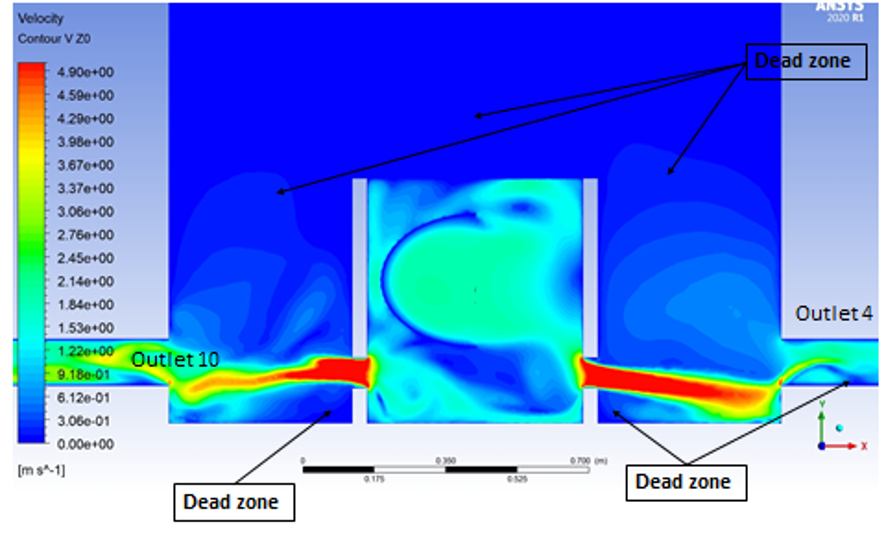

Velocity contour on plane z=0

close-up view Velocity contour on plane z=0 with focus on dead zones

close-up view Velocity contour on plane z=0 with focus on dead zonesDead Zone Distribution

close-up view

Velocity contour on plane Y=0 with focus on dead zones

close-up view

Velocity contour on plane Y=0 with focus on dead zones

Velocity contour on plane y=0

© Copyright 2023 MINTEC All Rights Reserved.