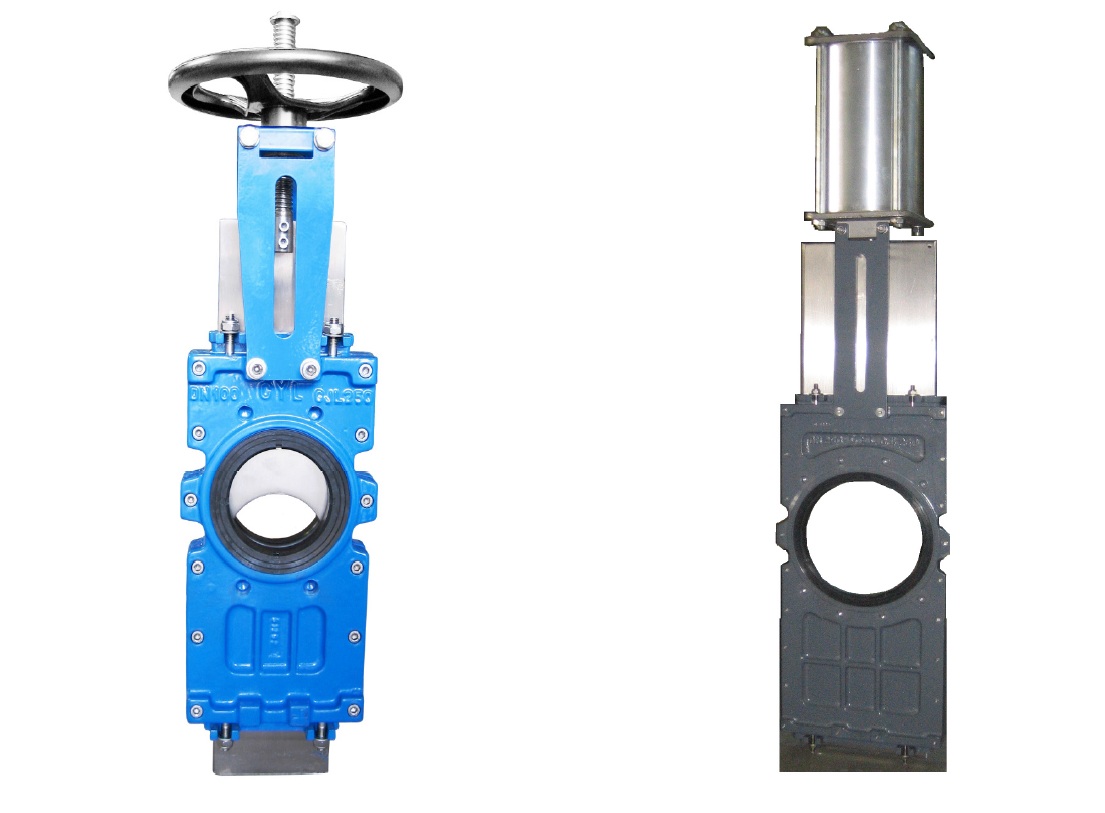

The company CYL in Spain manufactures various types of knife valves capable of operating at high pressures and different diameters. These valves can handle abrasive functions, high wear, and various viscosities. Due to its high production capacity, the company is capable of providing excellent after-sales services.

Exclusive representation certificate

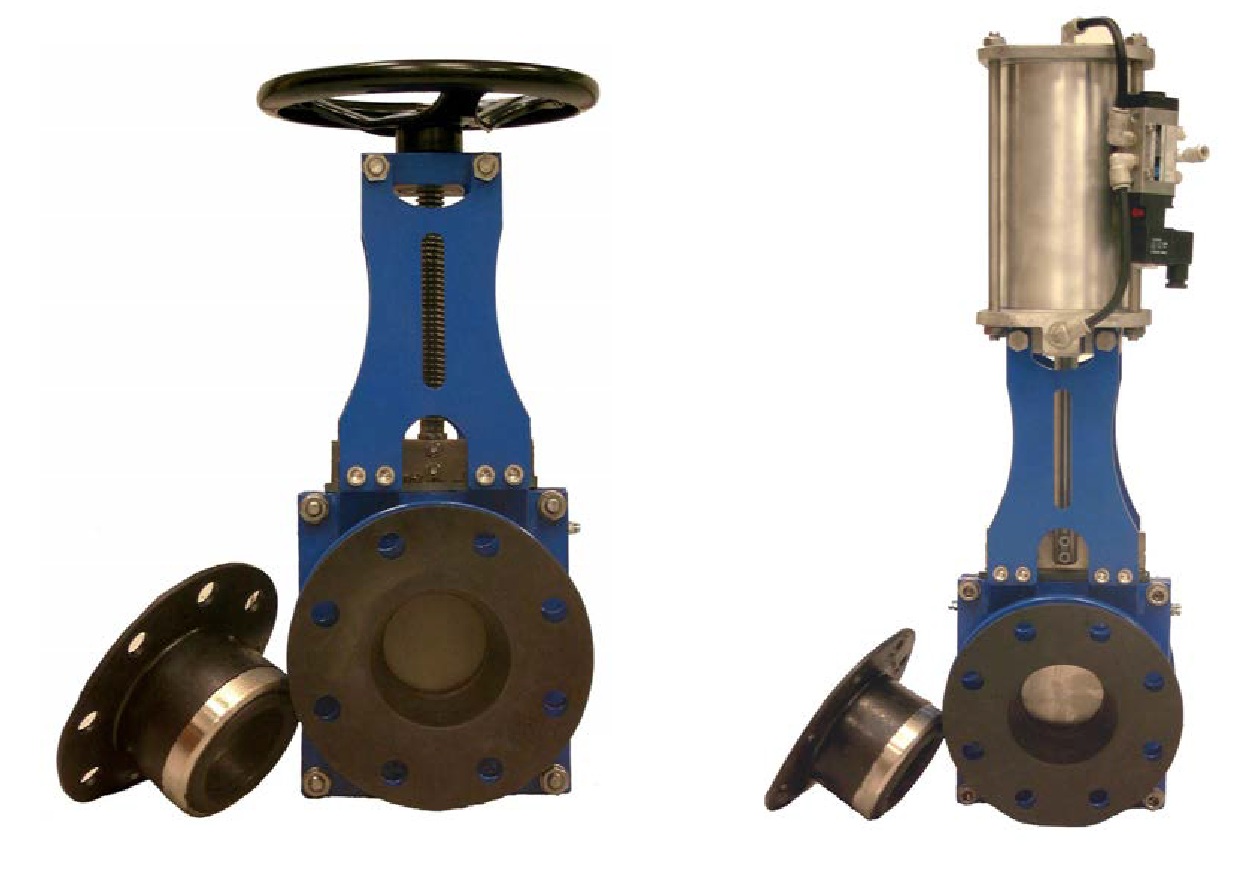

Below are brief explanations of the types of these valves:

knife valves XD

These valves are bi-directional and can be equipped with manual or automatic actuators. They are made with a bubble-tight chamber, which is suitable for shutting off flow from both directions.

knife valves MU

These valves are available in both single and double acting configurations and can be equipped with manual or automatic actuators. They feature an elastomer ring to reduce pressure during valve closure and a bubble-tight chamber for shutting off flow in one direction. This type of valve is suitable for various industrial applications, offering high performance against impurities and fluid abrasion.

knife valves PT

These valves can be produced in single and double acting versions and are adaptable with manual and automatic actuators. They feature an elastomeric ring to reduce pressure during valve closure and a bubble-tight chamber for shutting off flow in one direction. This type of valve is suitable for many industrial applications with high viscosity fluids.

knife valves SL

These valves can be produced in both single-acting and double-acting configurations and are compatible with manual and automatic actuators. They feature a double-sided seat ring designed for applications with high abrasion.

knife valves SK

These valves can be produced in single-acting and double-acting versions and are compatible with both manual and automatic actuators. They feature a double-sided seat ring, making them suitable for applications with high abrasion.

© Copyright 2023 MINTEC All Rights Reserved.